联系人:石经理

咨询电话:18838870707

咨询电话:0379-61127277

办公地址:洛阳市涧西区国家大学科技园

生产厂址:洛阳市洛新经济开发区

祝贺兆格环保全自动液压压榨机制备核桃油工艺优化成果入选核心期刊

祝贺兆格环保全自动液压压榨机制备核桃油工艺优化成果入选核心期刊

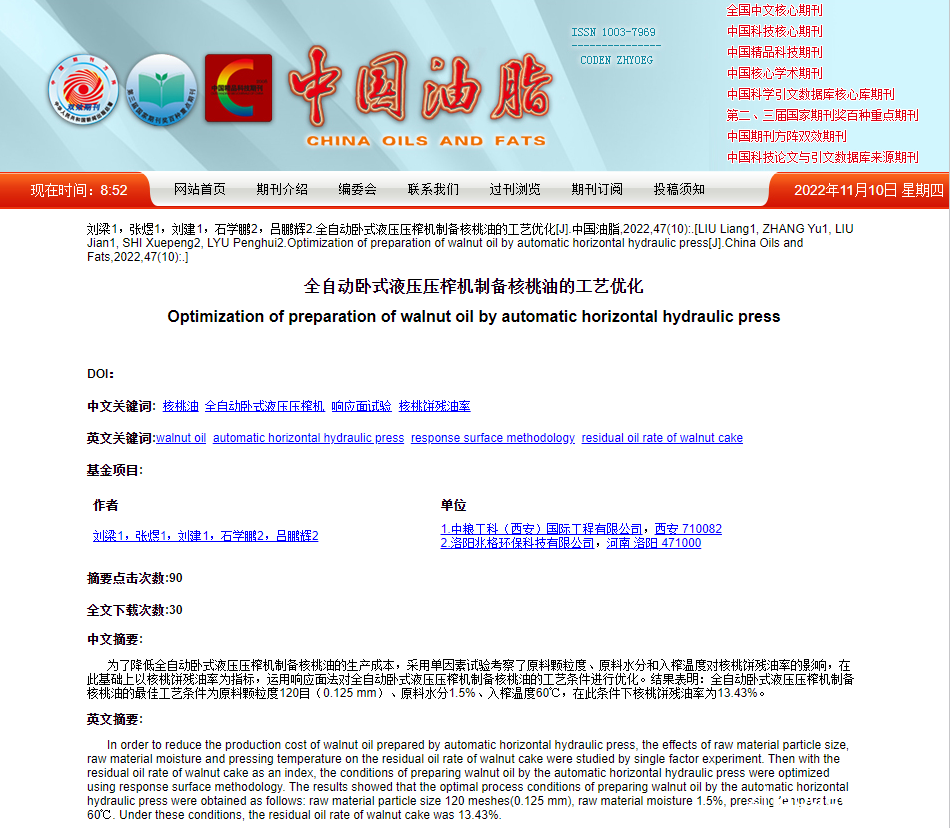

祝贺兆格环保关于全自动卧式液压压榨机制备核桃油的工艺优化的科研成果入选中国油脂等中国核心期刊

单位:1.中粮工科(西安)国际工程有限公司,西安 710082;2.洛阳兆格环保科技有限公司,河南 洛阳 471000

兆格环保是一家专业从事节能环保科技液压科技及固液分离科技的技术开发、技术转让、技术咨询、生产销售的高新技术企业,自主研发的全自动液压榨油机、化工原料压榨机、板框压滤机、固液分离设备、污泥处理设备、脱水干化设备、烘干设备等,在物理压榨、固液分离领域优势明显,为您提供专业的定制方案。

中文摘要:

为了降低全自动卧式液压压榨机制备核桃油的生产成本,采用单因素试验考察了原料颗粒度、原料水分和入榨温度对核桃饼残油率的影响,在此基础上以核桃饼残油率为指标,运用响应面法对全自动卧式液压压榨机制备核桃油的工艺条件进行优化。结果表明:全自动卧式液压压榨机制备核桃油的优秀工艺条件为原料颗粒度120目(0.125mm)、原料水分1.5%、入榨温度60℃,在此条件下核桃饼残油率为13.43%。

英文摘要:

In order to reduce the production cost of walnut oil prepared by automatic horizontal hydraulic press, the effects of raw material particle size, raw material moisture and pressing temperature on the residual oil rate of walnut cake were studied by single factor experiment. Then with the residual oil rate of walnut cake as an index, the conditions of preparing walnut oil by the automatic horizontal hydraulic press were optimized using response surface methodology. The results showed that the optimal process conditions of preparing walnut oil by the automatic horizontal hydraulic press were obtained as follows: raw material particle size 120 meshes(0.125 mm), raw material moisture 1.5%, pressing temperature 60℃. Under these conditions, the residual oil rate of walnut cake was 13.43%.